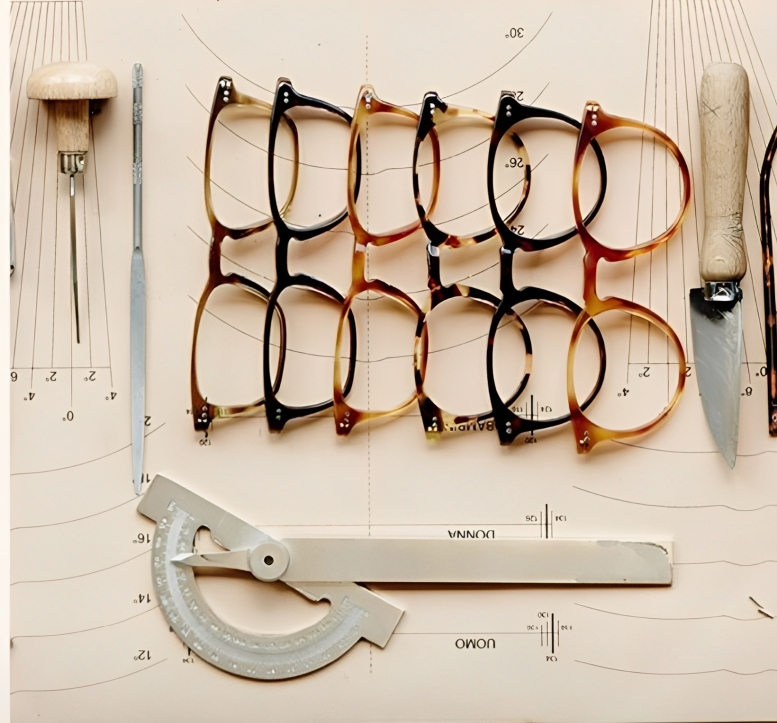

Our frames are created based on our brand philosophy, and we want our style to be present in each of our glasses. That's why our team of designers is in charge of capturing our inspiration and ideas so that our handcrafters can make them a reality.

Handmade in Spain with Mazzucchelli acetate made from natural cotton, resulting in a completely artisanal process that allows us to control the entire process and quality to obtain a product that is in line with our values. The production of each pair of glasses requires more than two weeks of work and two manufacturing processes.

All of our acetate frames are made from natural cotton. The process begins with the collection of cotton from plantations, which is then mixed and compressed for further processing.

Once the cotton is pressed, a wide range of pigments is selected. Once mixed, we achieve the colour combinations that we are looking for in each model.

After pigmenting the cotton, we obtain the acetate which then needs to be ironed into sheets of different thicknesses depending on the frame of the glasses.

Each of our frames is the result of our inspiration taken from somewhere in the world, and with the help of our designers, we can translate those ideas into a design that reflects the entire story behind it.

Each Archy eyeglass is handcrafted from a sheet of acetate, ensuring that no two Archy glasses are exactly alike.

This process is the longest and can last more than a week. Our frames go through different levels of polishing in our polishing drums. This process gives each frame a unique shine and finish.

One of the most important components of the entire process that allows us to extend the life of our glasses is the quality of the hinge. Therefore, we pay close attention to the quality of our hinges and their assembly process.

Like all works of art, they must have their signature.